INTELLIGENT MOTION TECHNOLOGY P. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to INTELLIGENT MOTION TECHNOLOGY P. LTD.

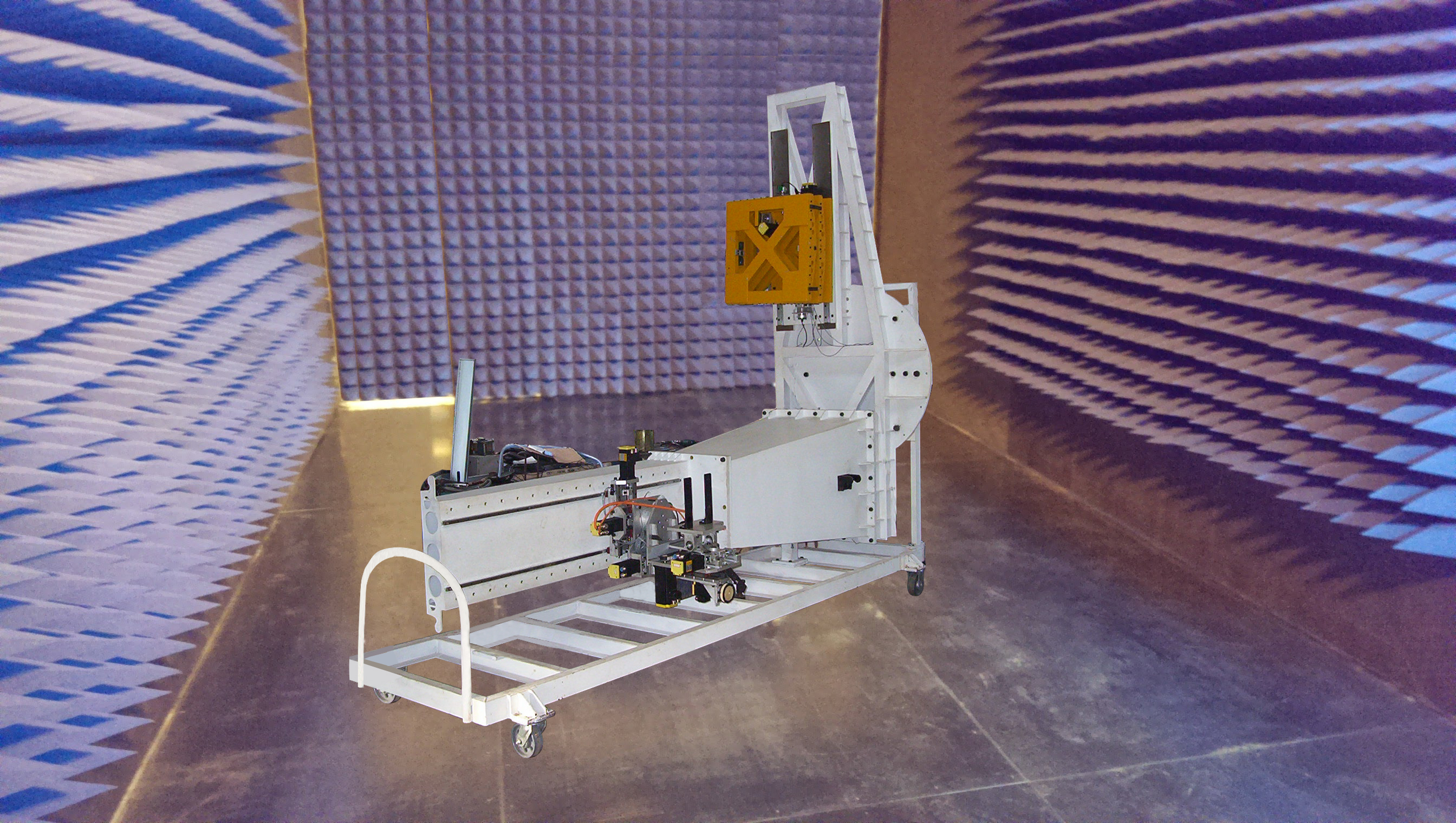

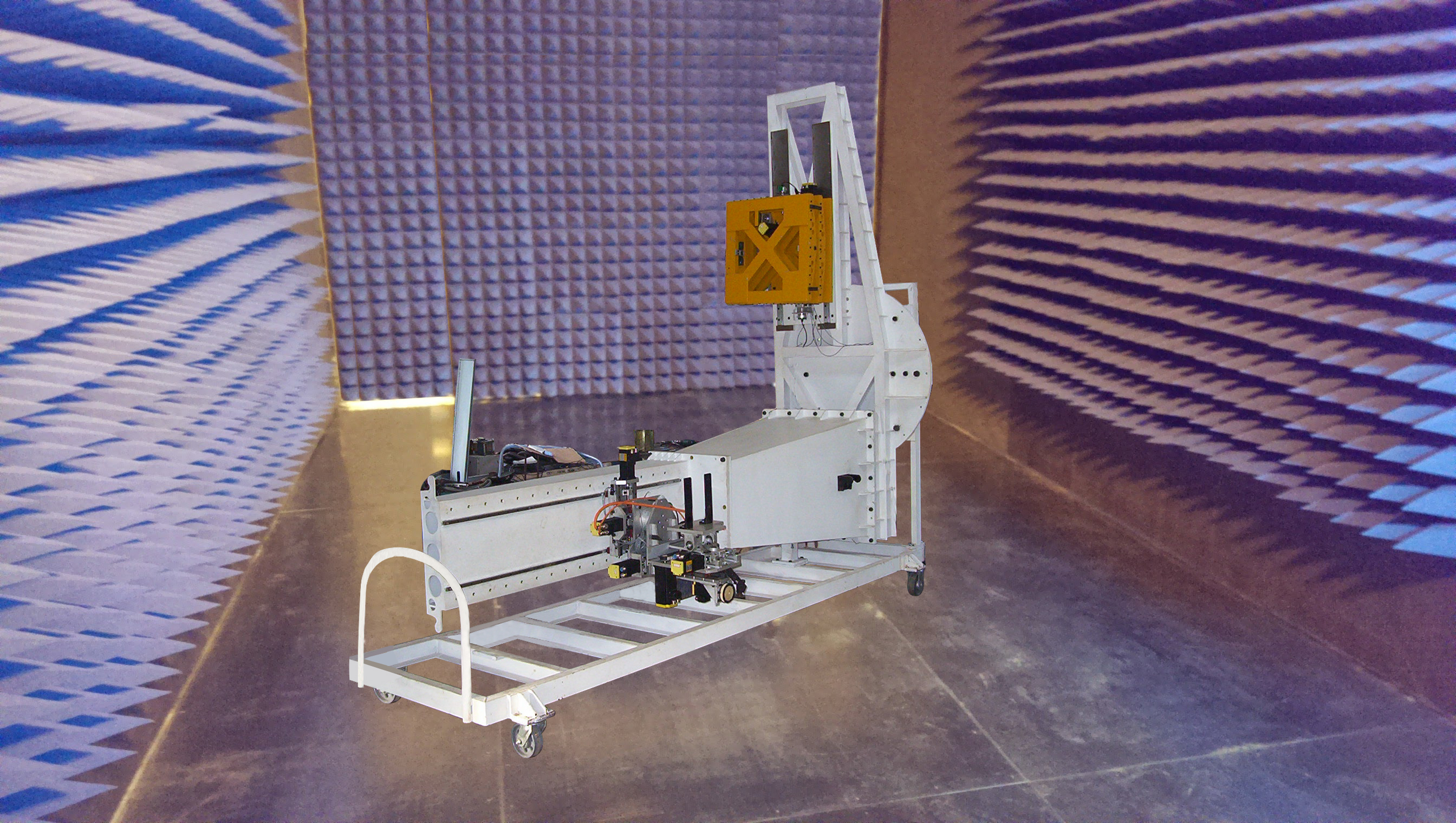

Antenna Control Servo System

ACSS is a high performance Servo System for tracking of Low Earth Orbit Satellites, Geo Synchronous Earth Orbit Satellites, Sun & Stars. ACSS is developed for precise motion control of the parabolic reflector type antennas using the state-of-the-art technology for modern digital control systems. Precise motion control is achieved by backlash removal in large gearboxes used with azimuth & elevation axis of antenna through usage of Dual Drive Counter Torque technique.

Implementation of cascade control for closing the loop using signal being received from satellite with the help of high performance servo-motion controls & high resolution absolute encoders.

ACSS has different operating modes like Standby, Manual, Slew, Designate, Program Track, Step Track, Monopulse Auto Track, Auto Sequence, Computer Designate Mode, Slave & Stow.

We have several installation of ACSS to Space Programs of Satellite Research Organization of India & overseas.

Antenna Control Sun Tracking System

|

Offset Reflector Antenna

750 mm diameter offset reflector antenna with elevation over azimuth mount has manual movement.

The elevation axis of the reflector is held in suitable bearings located on the rear side of the reflector. Screw jack type arrangement with low backlash machined screw and suitable hand wheel is provided for effecting reflector rotation about elevation axis. Rotary indexing table with a hand wheel provides azimuth rotation. A modular, rigid tripod with a provision for leveling is designed to carry both the axes & antenna assembly.

For angle measurement encoders are fitted on both the axes. Angle information is then displayed with Digital read out (DRO).

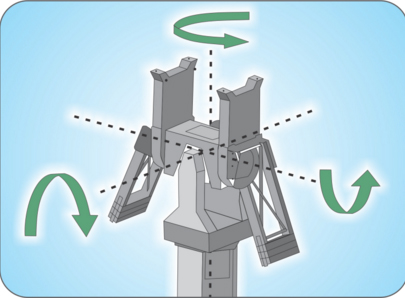

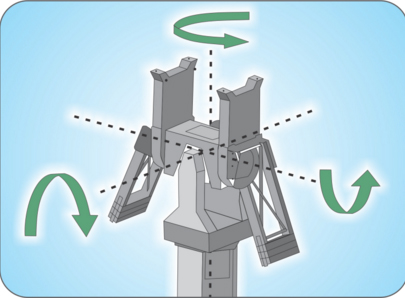

Stabilized Platform

Stabilized Platform or Antenna uses Gyro based Attitude Heading Reference System (AHRS) to sense the carrier vehicle’s Roll, Pitch and Yaw angles. This information is used to stabilize the payload against the movement of the carrier vehicle.

Stabilized Platform consists of 3 Axis construction with Azimuth, Elevation & Cross Elevation along with High performance Servo-Motion Controls and customized Graphical User Interface. Precision AHRS and GPS can be built into the system.

Applications including Satellite Tracking Stabilized Antenna onboard a ship, optical sight stabilization, stabilized cameras and mobile turret platforms.

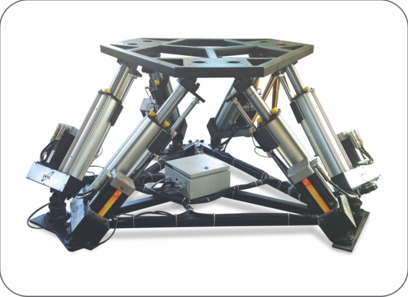

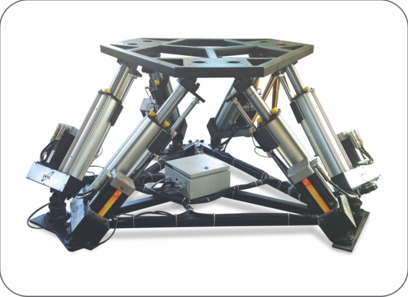

Motion Platforms

For today’s simulation market, Intelligent Motion Technology offers electronically driven 3 DOF & 6 DOF motion platforms using latest servo-motion technology & electro-mechanical systems and suitable for mid-range payloads upto 1500 kg on top of the motion platform base.

Surge, Sway, Heave, Roll, Pitch & Yaw movements are controlled using standard components like servo motors, planetary gearboxes & PC based motion controls with Ethernet connectivity.

Excursions, velocities & accelerations for all 3 DOF / 6 DOF movements are controlled & monitored through custom built Graphical User Interface.

These types of 3 DOF / 6 DOF Motion Platforms are perfectly suitable for all kinds of vehicle simulators. Training in 3 DOF / 6 DOF motion simulators significantly reduced costs, risks and time compared to training in real vehicles by creating illusion of reality combined with a economical cost of ownership. Safe operations, energy efficient, low maintenance, optimal motion control, smooth movements are benefits to the end users.

Diamond Cutting Machines

Diamond Sawing and Shape Cutting Machines are used to saw the diamonds with low power Laser. Several shapes of aesthetic importance can be cut with the machine.

Low power laser is used as cutting tool. Computerized vision system is used for assistance during sawing and shape cutting. The machine is based on Cartesian X-Y-Z movements powered by linear servo motors. Ball screws are avoided for higher acceleration and trouble free operations. The control system uses advanced motion controller. Features like Auto changeover and fixture to cut 20 or 40 diamonds enhances the machine capability.

Continuous development in the software has enabled us to increase the throughput, to reduce weight loss & also to minimize diamond breakage

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.